In today’s fast-paced and competitive business landscape, efficient inventory management is paramount for success. From manufacturing to retail, every industry relies heavily on maintaining optimal stock levels to meet customer demand while minimizing costs. In recent years, the integration of Artificial Intelligence (AI) into inventory management processes has emerged as a game-changer, offering unprecedented levels of accuracy, efficiency, and cost-effectiveness.

AI in inventory management refers to the utilization of advanced algorithms and machine learning techniques to streamline the entire inventory lifecycle, from procurement to distribution. This revolutionary technology enables businesses to make data-driven decisions, automate routine tasks, and forecast demand with remarkable precision.

One of the key advantages of AI in inventory management is its ability to analyze vast amounts of data in real-time. Traditional inventory management systems often struggle to cope with the sheer volume and complexity of data generated by modern supply chains. However, AI-powered algorithms excel at processing large datasets, identifying patterns, and extracting actionable insights.

Demand forecasting is a critical aspect of inventory management, as it allows businesses to anticipate customer needs and optimize stocking levels accordingly. AI algorithms leverage historical sales data, market trends, seasonal variations, and external factors to generate accurate demand forecasts. By continuously learning from past performance and adjusting predictions in real-time, AI systems help businesses minimize stockouts, reduce excess inventory, and improve overall inventory turnover.

Furthermore, AI algorithms can optimize inventory replenishment strategies by dynamically adjusting reorder points and order quantities based on changing demand patterns and lead times. By factoring in variables such as supplier performance, transportation costs, and economic factors, AI-driven inventory management systems ensure that businesses maintain optimal stock levels while minimizing carrying costs and stockouts.

Inventory optimization is another area where AI excels. Traditional methods of inventory optimization often rely on static rules and heuristics, which may not adapt well to dynamic market conditions. In contrast, AI algorithms continuously analyze inventory data, supply chain dynamics, and customer behavior to identify opportunities for improvement. Whether it’s determining the optimal product mix, SKU rationalization, or safety stock levels, AI-driven optimization algorithms help businesses maximize profitability and efficiency.

Moreover, AI in inventory management enables predictive maintenance, which can significantly reduce downtime and maintenance costs. By analyzing equipment performance data, sensor readings, and historical maintenance records, AI algorithms can anticipate potential failures and schedule maintenance proactively. This proactive approach not only extends the lifespan of critical assets but also ensures smooth operations and enhances overall productivity.

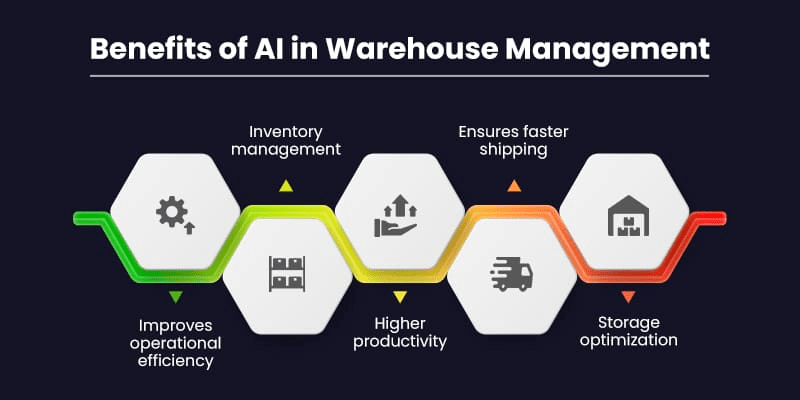

In addition to improving operational efficiency, AI in inventory management also enhances the customer experience. By ensuring product availability and reducing order fulfillment times, businesses can enhance customer satisfaction and loyalty. AI-driven inventory management systems enable businesses to offer accurate delivery estimates, optimize shipping routes, and provide real-time visibility into order status, thereby enhancing the overall shopping experience for customers.

Furthermore, AI-powered inventory management systems facilitate omnichannel fulfillment, allowing businesses to seamlessly integrate online and offline sales channels. Whether it’s fulfilling orders from brick-and-mortar stores, warehouses, or third-party vendors, AI algorithms optimize order routing and allocation to minimize shipping costs and delivery times. This flexibility enables businesses to meet customer expectations for fast, reliable, and convenient delivery options.

Despite the numerous benefits of AI in inventory management, implementing and integrating AI-driven solutions can be challenging for businesses. It requires significant investments in technology infrastructure, data integration, and talent acquisition. Moreover, businesses must overcome organizational barriers and cultural resistance to change to fully realize the potential of AI in inventory management.

However, the long-term benefits far outweigh the initial challenges. Businesses that embrace AI in inventory management gain a competitive edge by improving efficiency, reducing costs, and enhancing customer satisfaction. Moreover, as AI technology continues to evolve, the potential for innovation and optimization in inventory management is virtually limitless.

In conclusion, AI has revolutionized inventory management by enabling businesses to leverage data-driven insights, optimize stocking levels, and enhance operational efficiency. From demand forecasting to inventory optimization and predictive maintenance, AI algorithms offer unprecedented levels of accuracy, agility, and scalability. By embracing AI in inventory management, businesses can stay ahead of the curve in today’s dynamic and competitive marketplace.

Leave a comment