Introduction

Generative AI, a cutting-edge technology at the intersection of artificial intelligence and manufacturing, is transforming industries worldwide. In manufacturing specifically, this technology holds the potential to revolutionize processes, enhance efficiency, and drive innovation like never before.

What is Generative AI?

Generative AI refers to a class of algorithms that learn patterns from large datasets and can generate new content based on that learning. Unlike traditional AI systems that are rule-based and limited by human input, generative AI can autonomously create designs, models, and solutions tailored to specific criteria and constraints.

Applications in Manufacturing

- Design Optimization

Generative AI algorithms excel in optimizing designs based on multiple parameters such as cost, material efficiency, and performance metrics. By exploring numerous design possibilities, these algorithms can discover solutions that human designers might overlook, leading to more efficient and innovative product designs. - Prototyping and Testing

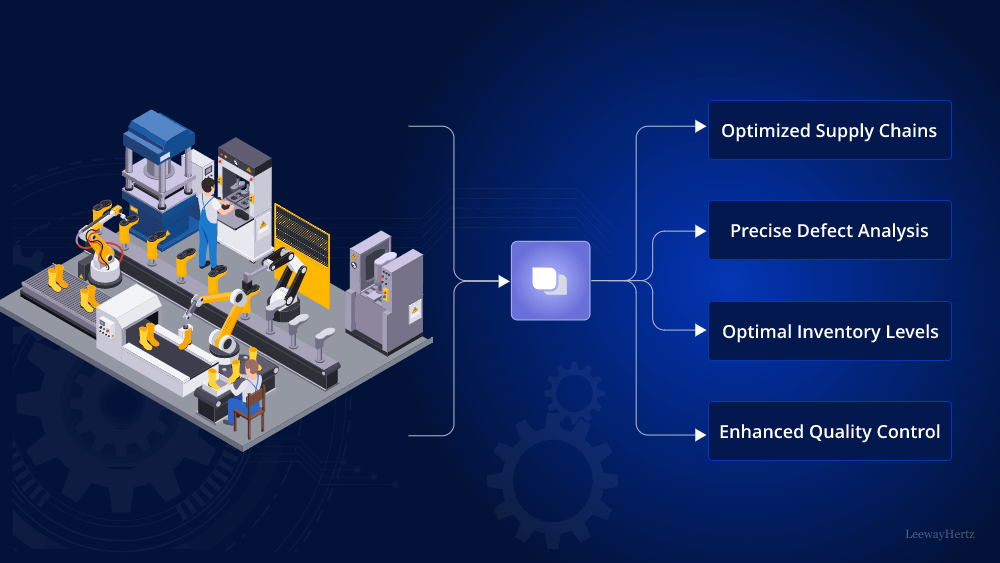

Rapid prototyping is crucial in manufacturing to validate designs before full-scale production. Generative AI can speed up this process by generating and testing prototypes virtually, reducing costs and time associated with physical prototyping. This capability enables manufacturers to iterate designs quickly and refine products more effectively. - Supply Chain Management

Efficient supply chain management is essential for manufacturing success. Generative AI can analyze supply chain data to optimize inventory levels, predict demand fluctuations, and identify cost-saving opportunities. By leveraging this technology, manufacturers can streamline operations and enhance overall supply chain resilience. - Predictive Maintenance

Machinery downtime can be costly for manufacturers. Generative AI algorithms can predict equipment failures by analyzing real-time sensor data and historical maintenance records. This proactive approach allows for timely maintenance interventions, reducing unplanned downtime and extending equipment lifespan.

Case Studies: Real-World Impact

- General Electric (GE)

GE Aviation utilized generative design to develop a jet engine bracket. By applying generative AI algorithms, they reduced the bracket’s weight by 84% while maintaining its structural integrity. This innovation not only improved fuel efficiency but also demonstrated significant cost savings in manufacturing. - Volkswagen

Volkswagen employed generative AI to optimize the design of a seatbelt bracket. Through iterative design exploration, they achieved a 40% reduction in weight without compromising safety standards. This application showcases how generative AI can enhance both product performance and manufacturing efficiency.

Challenges and Considerations

While generative AI offers immense potential, several challenges must be addressed:

- Data Quality: Generative AI algorithms rely on vast datasets. Ensuring data accuracy and relevance is crucial for generating reliable outputs.

- Ethical Concerns: As AI systems become more autonomous, ethical considerations around accountability, bias, and privacy must be carefully managed.

- Skill Requirements: Implementing generative AI may require upskilling the workforce to effectively leverage and manage AI-driven technologies.

Future Outlook

The future of generative AI in manufacturing looks promising:

- Personalized Manufacturing: AI-driven customization of products based on individual customer preferences.

- Sustainability: Optimizing designs for minimal environmental impact through material efficiency and energy conservation.

- Collaborative AI: Integrating generative AI with human creativity to foster new innovations and solutions.

Conclusion

Generative AI represents a paradigm shift in manufacturing, offering unprecedented opportunities for efficiency, innovation, and competitiveness. As manufacturers embrace this technology, they can expect to see improvements across all stages of production—from design to supply chain management and beyond. While challenges exist, the potential rewards of harnessing generative AI are transformative, positioning early adopters at the forefront of industry advancement. Embracing generative AI isn’t just about staying competitive; it’s about leading the charge toward a more efficient, sustainable, and innovative future in manufacturing.

Read More: https://www.leewayhertz.com/generative-ai-platform-for-manufacturing/

Leave a comment