Introduction

In the rapidly evolving world of technology, Artificial Intelligence (AI) stands out as a revolutionary force, transforming various sectors. One of the most impactful applications of AI is in predictive maintenance, a proactive approach to managing the upkeep of machinery and equipment. By leveraging AI in predictive maintenance, businesses can foresee equipment failures, optimize maintenance schedules, and reduce operational costs. This article explores how AI is reshaping predictive maintenance, its benefits, and real-world applications.

Understanding Predictive Maintenance

Predictive maintenance is a strategy that involves monitoring the condition of equipment during normal operation to predict when maintenance should be performed. This method minimizes downtime and maximizes equipment lifespan, unlike traditional maintenance strategies which are either reactive (repairing after a failure) or preventive (regular maintenance regardless of condition).

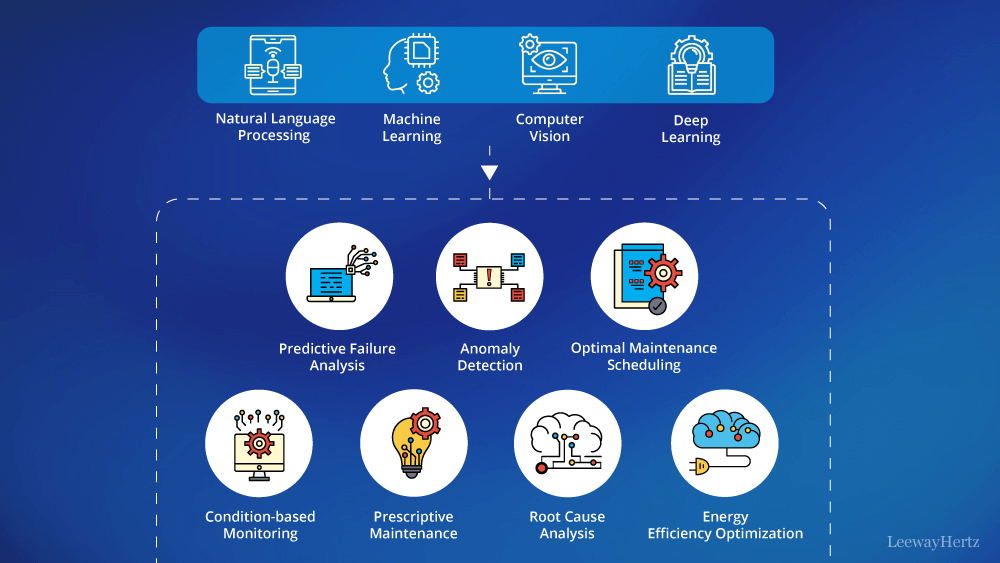

The Role of AI in Predictive Maintenance

AI in predictive maintenance enhances the processes by analyzing vast amounts of data generated by machinery. These datasets include operational parameters, historical maintenance records, and real-time sensor data. AI algorithms process this information to identify patterns and predict potential failures before they occur. Here’s how AI contributes to predictive maintenance:

Data Analysis and Pattern Recognition

- AI algorithms, particularly machine learning models, can sift through large volumes of data to detect anomalies and patterns that might indicate an impending failure. This capability surpasses human analysis, providing more accurate predictions.

Real-Time Monitoring and Alerts

- AI systems continuously monitor equipment conditions through IoT (Internet of Things) sensors. These sensors collect real-time data on various parameters like temperature, vibration, and pressure. AI analyzes this data instantaneously, providing alerts if any parameter deviates from the norm, signaling potential issues.

Maintenance Scheduling Optimization

- By predicting when a component is likely to fail, AI helps in scheduling maintenance activities at the most opportune times. This prevents unnecessary maintenance, reducing downtime and extending the life of the equipment.

Enhanced Decision Making

- AI systems can provide maintenance teams with actionable insights, helping them make informed decisions. These insights can range from identifying which parts need attention to suggesting the most effective maintenance procedures.

Benefits of AI in Predictive Maintenance

Implementing AI in predictive maintenance offers several significant advantages:

Reduced Downtime

- Predictive maintenance ensures that maintenance activities are performed only when necessary, reducing unplanned downtimes significantly. This leads to continuous operations and better productivity.

Cost Savings

- By preventing unexpected equipment failures, businesses save on costly emergency repairs and avoid production losses. Additionally, optimized maintenance schedules reduce the frequency of routine checks and part replacements, leading to cost efficiency.

Increased Equipment Lifespan

- Timely maintenance based on accurate predictions helps in maintaining the equipment in optimal condition, thereby extending its operational lifespan.

Improved Safety

- Regular monitoring and timely maintenance reduce the risk of catastrophic equipment failures, enhancing the safety of the workplace.

Data-Driven Insights

- AI systems provide valuable data-driven insights that can be used to improve overall operational efficiency and inform future maintenance strategies.

Real-World Applications

Various industries are harnessing the power of AI in predictive maintenance to optimize their operations:

Manufacturing

- In manufacturing, AI monitors machinery health to prevent breakdowns that could halt production lines. For example, AI systems in automotive manufacturing can predict when a robotic arm might fail, allowing for preemptive maintenance and avoiding production delays.

Energy Sector

- The energy industry uses AI to monitor critical infrastructure like turbines and generators. Predictive maintenance ensures these vital components are always operational, minimizing downtime and maintenance costs.

Transportation

- Railways and airlines leverage AI to predict maintenance needs for trains and aircraft. This not only ensures safety but also improves scheduling and reduces delays caused by equipment failures.

Healthcare

- In healthcare, predictive maintenance powered by AI ensures that critical medical equipment, such as MRI machines and ventilators, remain functional, reducing the risk of equipment failure during critical procedures.

Conclusion

AI in predictive maintenance is a game-changer, offering unparalleled benefits in terms of efficiency, cost savings, and operational reliability. By continuously monitoring equipment and predicting failures, AI enables businesses to move from a reactive to a proactive maintenance approach. As AI technology continues to evolve, its role in predictive maintenance will only become more significant, driving innovation and efficiency across various industries. Embracing AI in predictive maintenance is not just a technological upgrade; it’s a strategic move towards a more efficient and reliable future.

Leave a comment