Introduction Manufacturing is undergoing a revolution, thanks to advances in technology. Among these innovations, generative AI stands out as a transformative force. Generative AI for manufacturing leverages powerful algorithms to design, optimize, and enhance production processes. This technology has the potential to reshape industries by improving efficiency, reducing costs, and fostering innovation.

What is Generative AI for Manufacturing?

Generative AI refers to artificial intelligence systems that can create new content or solutions based on existing data. In the manufacturing sector, this means using AI-driven models to design products, streamline workflows, and optimize supply chains. Unlike traditional AI, which typically focuses on analyzing existing patterns, generative AI is proactive, generating novel ideas and solutions.

For example, Generative AI in Manufacturing can help design lightweight yet strong components for vehicles or aircraft. These AI-driven designs often surpass human-engineered counterparts in terms of performance and cost-effectiveness. Moreover, it can simulate various manufacturing scenarios, helping engineers identify potential bottlenecks or inefficiencies before production begins.

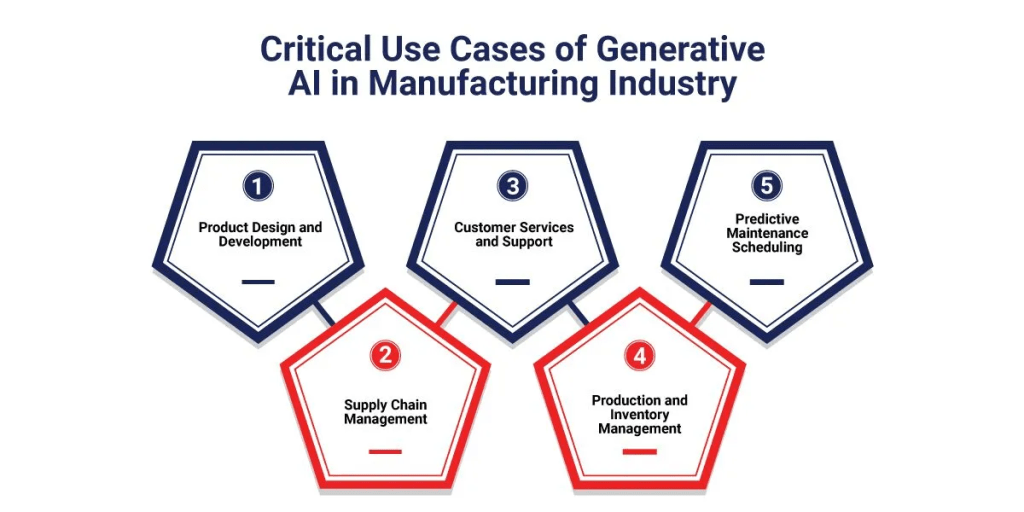

Applications of Generative AI in Manufacturing

- Product Design and Development Generative AI enables rapid prototyping and innovative product designs. By analyzing large datasets, it can suggest unique configurations that improve functionality and reduce material usage. This accelerates time-to-market and helps manufacturers stay competitive.

- Process Optimization Manufacturing processes often involve complex workflows. Generative AI for manufacturing can model these workflows to identify inefficiencies. For instance, AI can recommend adjustments to machinery placement on the factory floor, leading to smoother operations and lower energy consumption.

- Supply Chain Management The manufacturing supply chain is a critical component of production. Generative AI can analyze supply chain data to predict demand fluctuations, identify the best suppliers, and optimize inventory levels. This ensures timely delivery of materials and reduces waste.

- Quality Control and Maintenance Generative AI can analyze production data in real-time to detect defects or deviations from quality standards. Additionally, predictive maintenance models can forecast equipment failures before they occur, minimizing downtime and repair costs.

- Custom Manufacturing With the rise of personalization, manufacturers are increasingly tasked with producing custom products. Generative AI simplifies this by enabling scalable mass customization. It ensures that each unique design adheres to manufacturing constraints while meeting customer expectations.

Benefits of Generative AI for Manufacturing

- Increased Efficiency By automating design and process optimization, generative AI reduces the time and resources needed for production. This allows manufacturers to focus on innovation rather than routine tasks.

- Cost Savings Optimized processes and predictive maintenance translate to significant cost reductions. Generative AI’s ability to minimize waste and energy consumption further contributes to overall savings.

- Enhanced Innovation Generative AI fosters creativity by providing engineers and designers with a multitude of potential solutions. This leads to breakthroughs in product development that may not have been possible through traditional methods.

- Sustainability Manufacturing industries are under increasing pressure to adopt sustainable practices. Generative AI supports this goal by reducing material usage, energy consumption, and waste. Additionally, it can aid in designing recyclable and eco-friendly products.

- Adaptability The manufacturing landscape is constantly evolving. Generative AI’s ability to analyze and adapt to new data ensures that manufacturers can remain agile and responsive to market changes.

Challenges of Implementing Generative AI in Manufacturing

While generative AI offers numerous benefits, implementing it in manufacturing is not without challenges. These include:

- High Initial Costs Deploying AI systems requires significant investment in hardware, software, and training. Smaller manufacturers may find these costs prohibitive initially.

- Data Dependency Generative AI relies on large datasets to function effectively. Manufacturers need to ensure they have access to high-quality data to achieve optimal results.

- Integration with Existing Systems Many manufacturers operate with legacy systems that may not be compatible with generative AI technologies. Integrating these systems requires careful planning and execution.

- Skill Gap The adoption of generative AI demands skilled professionals who can develop, implement, and maintain these systems. Addressing the skill gap in the workforce is essential for successful implementation.

The Future of Generative AI for Manufacturing

The future of generative AI in manufacturing is bright. As the technology matures, it is expected to become more accessible and cost-effective, allowing even small and medium-sized manufacturers to benefit. Innovations in AI algorithms and hardware will further enhance the capabilities of generative AI, leading to smarter, more efficient factories.

Additionally, as sustainability becomes a priority, generative AI’s role in creating eco-friendly manufacturing processes and products will become increasingly significant. Collaborative efforts between researchers, manufacturers, and policymakers can accelerate the adoption of this transformative technology.

Conclusion Generative AI for manufacturing is not just a technological advancement; it is a paradigm shift. By enabling smarter design, optimizing processes, and improving sustainability, generative AI is poised to revolutionize the manufacturing industry. While challenges exist, the benefits far outweigh the hurdles. Embracing this technology will empower manufacturers to innovate, compete, and thrive in a rapidly changing world.

Leave a comment